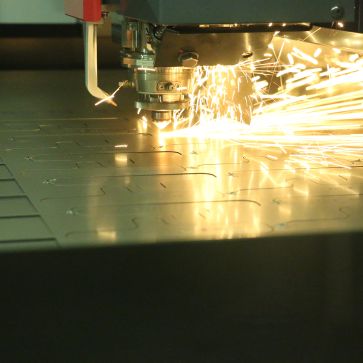

Precision Laser Cutting

Seaberg Industries is a long standing manufacturing company located centrally in Davenport, Iowa. Our location near the Mississippi River allows us to easily get fabrication supplies and to ship out orders. We are located within a day of all of your major Midwestern cities, including Chicago and Milwaukee. We also avoid excessive downtime and missed deadlines by having the capabilities to handle high volume jobs without supply and manpower interruption.

We are DNV certified to ISO 9001-2015 (Certificate # 03297-2004-AQ-HOU-ANAB) and Caterpillar and CNH Certified Since 1986.

Cost Reduction & Increased Production

Another manufacturing process, added to all the other services we provide, is precision laser cutting. The precision laser cutting process not only reduces cost for our customers, but also provides many other advantages. Our laser cutting services can eliminate the need for machining on many of our engineering jobs, enabling you to save money on overall manufacturing costs.

Our processes allow us to meet projects with high volume capacity. Essentially it offers an affordable and accurate way of producing almost any shape in plate or sheet metal. In addition to maximizing material usage for your project.

Advantages Of Precision Laser Cutting

- An edge with a high-quality surface finish, compared to material cut by other traditional methods

- A reduced chance of material warping, since laser systems have a small heat-affected zone

- Reduced contamination of the part; this presents certain advantages over other traditional mechanical cutting techniques since there is no cutting edge which can become contaminated, by the material or contaminate the material

- Laser cutting also allows the ability to cut small diameter holes with complex detail and good edge quality in either sheet or plate, ensuring precision parts

- The ability to cut materials that are difficult or impossible to cut by more traditional means

- Custom, high powered, laser technology allows for the cutting of complex shapes without the need for tooling, and at a similar or faster speed than other cutting methods

- Ultimately this process not only uses less energy, but the laser beam does not wear during the process. Seaberg Industries has two, 4000 watt CO2 lasers which typically run anywhere from 20 gauge up to 5/8” (16 mm) thickness. Our lasers also have the capability of a precision of +/- 0.002" (0.05mm) and repeatability = +/- .0004" (0.01mm).

A critical element is our set ups. By utilizing nesting software, we are able to maximize the use of material, thereby reducing the cost of the parts, as mentioned above. As with all of our equipment, we have regularly scheduled maintenance intervals on each laser.

Finally with our custom laser cutting we are able to automate the etching process, by etching identification on the parts that are required. This ensures the consistency of identification and eliminates any variability. Seaberg is a manufacturing company, whose high powered laser systems you can count on to deliver high quality stainless steel products.